Shoemaster® is continuing its innovation process, accelerated by the acquisition of the well-known software house by Atom Group. During Simac Tanning Tech 2018, it will preview some of its new product versions, focussing specifically on technological design and production process integration, in line with the Industry 4.0 paradigm.

One of its presented packages namely “PRODUCTION” contains a set of dedicatedtools for the management of technical sheets, bill of materials, consumption calculations and costing.

The system based on an open technology database, can be easily connected to any ERP system, and has been developed to improve the integration between the design and the production world when considering the globalisation of modern shoe production.

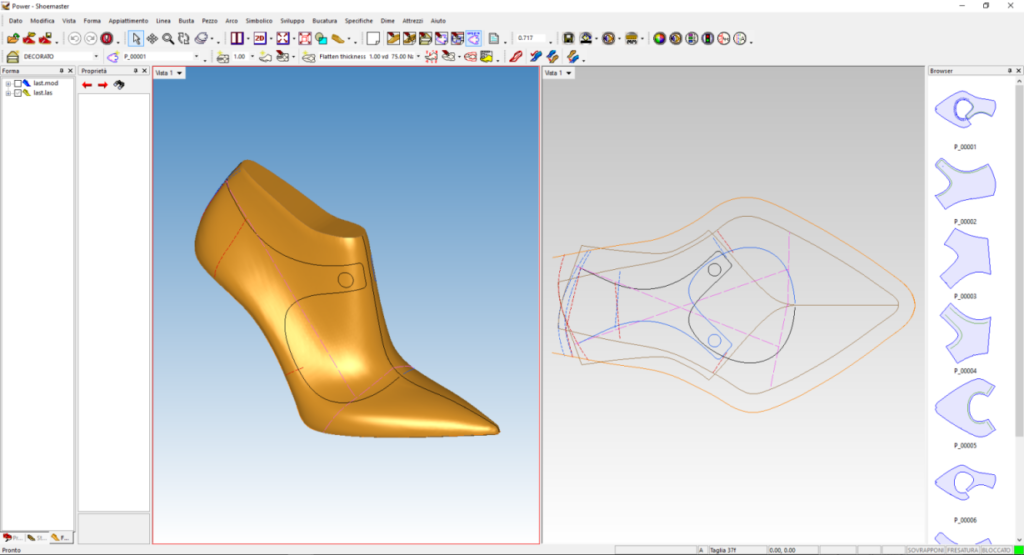

The concept of “integration” is applied within Shoemaster® on many technological levels such as the connection between 3D design and 2D pattern engineering or between the CAD system and an ERP platform and last but not least between shoe engineering, development and production. In each of this areas Shoemaster® is developing specific solutions to provide the market with an expansive platform for the entire industrial process.

Shoemaster’s innovation doesn’t stop at the development of new products, but also includes the continuous improvement and development of its well-known 3D solutions, such as the latest Shoemaster® ENGINEER-Pro package, which contains some new automatic flattening algorithms for complex lasts shapes. These new features will eliminate manual operations in the style/engineering phase, helping to reducing potential errors by standardizing the process. In this way Shoemaster® aims to reach one of its goals, to provide its customers with a unique digital platform to cover all their design and production requirements for the modern shoe manufacturer.

SHOEMASTER® HEADS TOWARDS PROCESS INTEGRATION

February 2018•Simac Tanning Tech

TAGEvents / fairs

- March 2025FIMEC

- February 2025IILF – India International Leather Fair

- September 2022SIMAC TANNING TECH 2022